News Room

Howdon Protection For Wind Machines

3rd April 2024

For over 20 years, Howdon has been providing the drive protection on Wind Machines designed and manufactured by Orchard-Rite Inc., USA.

As a leading company in the science of crop protection, Orchard-Rite produce a range of Wind Machines to protect fruit such as apples, apricots, peaches, cherries, grapes, avocados and kiwis, from spring frost or winter freezes.

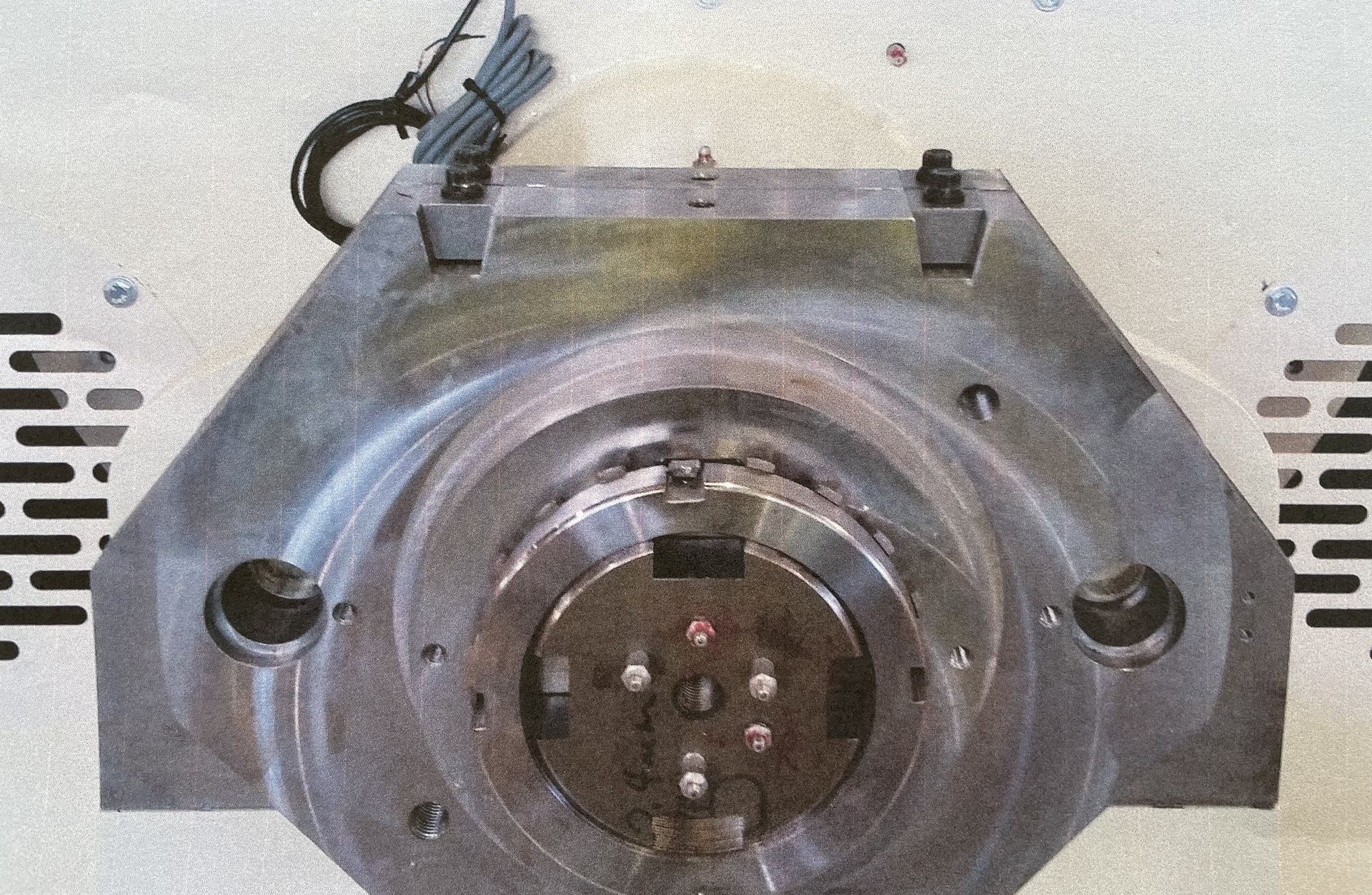

Orchard-Rite Stationary Wind Machines are driven by Ford V8 or CAT C7.1 and CAT C4, E4 engines but should the engine begin to surge or run erratically, say by running out of fuel, the gearbox/drivetrain could be damaged. Howdon designed a Wedgegard Coupling to uncouple the drivetrain to minimise any damage.

“The Wedgegard / breakaway coupler is fitted to the output shaft of the lower gearbox in the engine assembly as highlighted on the picture, and is easily accessible for simple manual reset following any release caused by an overload”, said Andrew Weber, Operations Manager at Orchard-Rite.

“Our engineers at Howdon are always happy to design bespoke products to meet the drive protection requirements of specific industries”, commented Fethi Slama, Howdon Sales Director.

Pictures courtesy of Orchard-Rite, Inc.

Howdon appointed as official UK distributor for Svendborg Brakes

6th March 2024

Howdon Power Transmission Ltd are pleased to announce that Svendborg Brakes, a Regal Rexnord group company, has appointed Howdon as their official distributor for the UK.

Svendborg Brakes are innovators in industrial brake configurations and pioneers with hydraulic braking systems, power transmission and motion control products. Their wide range of quality products is used in many different sectors, including renewable energy, mining, cranes, oil and gas.

Please watch the video for more information about Svenborg Brakes, or for details of the Svendborg Brakes products available via Howdon, please click below.

Howdon Protection For Pellet Mills

10th February 2024

Howdon Power Transmission Ltd has enjoyed a long relationship with Andritz Inc., a world leading company in the design and manufacture of Pellet Mills for feed production.

Howdon has supplied a range of Wedgegard™ products to provide safety stop production to the roll adjustment spindles on Pellet Mills, processing animal feed and biofuel products.

The engineers at Andritz endeavour to give customers the highest performance, reliable ease of maintenance, and low energy consumption equipment.

The Howdon Wedgegard™ shear pin solution is integrated into the Mill design, and protects against damage from foreign objects.

A hydraulic system is designed to open all roll-adjusting cylinders automatically upon shear pin release, which provides increased protection against damage.

Then the Howdon Wedgepins are simply replaced, reducing any excess loss in production time.

The fine-tuned designs offered by Andritz provide highly efficient pelleting, combining well-proven and long established technology with highly efficient power transmission.

Howdon is pleased to support Andritz in their programme of continuous development.

Images copyright ©Andritz, Inc., Muncy, PA, USA.

New Appointment at Howdon

1st January 2024

Howdon Power Transmission Ltd are pleased to announce the appointment of Mr. Fethi Slama as the company's Sales Director.

Fethi is married with two children and has worked in international sales for many years. He is multilingual, speaking 5 languages, with deep expertise in Howdon's products, Torque Limiters, Twiflex products, Svendborg products and many others. He also has extensive experience in business development, analytics and various sales tools such as the Direct Industry platform, Salesforce CRM, etc.

For the past five years he has led Howdon's global sales activities, promoting the company's business in the UK and overseas, and dealing with all our distributors and clients.

Fethi is based at Howdon's head office in Stroud, Gloucestershire, where he looks forward to continuing to support our growing list of satisfied customers and agents across the world.

Howard P Miles, Managing Director

Howdon Drive Protection in the Renewable Energy Industry

Alvan Blanch Development Company Ltd are a company with over 70 years of engineering experience producing processing machinery for the agricultural industry. As the need for sustainable alternatives to fossil fuels there has been a growing interest in the use of biomass materials. Alvan Blanch has produced a range of drying and processing machines for woodchip, digestate, grass, straw and animal manure.

Howdon has worked with Alvan Blanch in providing drive protection units for machines processing different materials including seaweed and wood. These Wedgegard Units are required to maintain their integrity in difficult working conditions.

The pictures below show a Howdon Wedgegard S Hub providing reliable drive protection on a Biomass Woodchip Drying Machine.

Images copyright ©Alvan Blanch Group.

Howdon Wedgegard giving drive protection on Seaweed Processing Plant

Usit Asco Limited is a company based in the Scottish Isle of Usit and has promoted the business of harvesting nutrient-rich seaweed from the coast of the Outer Hebrides. Seaweed is utilised across a variety of uses including animal and human consumption, fertiliser and biomass.

Drying seaweed prior to processing can extend the product by up to two years. Alvan Blanch designed and manufactured the CV 22000 Seaweed Conveyor and Batch Dryer fitted with Howdon Wedgegard Overload Drive Protection for Usit Asco.

Image copyright ©Alvan Blanch Group.

Here at Howdon we have provided Torque Limiters, Couplings, Brakes and Thrusters to many happy customers over the years. Here's what just a few of them have said about working with us...

"We had been developing a test rig for two years to help a client test a manual clutch system for new Hybrid and Electric vehicles.

The problem was that we needed a torque limiter coupling that could run up to speeds of 6500 rpm and 900 Nm, but be small enough to fit into our newly designed test rig.

This was a quick turnaround job and Howdon's customer service was excellent, answering all our technical queries straight away."

PAUL REID

Project Manager at Zytek Automotive Ltd, Continental Engineering Services

"The gimbal was a pretty spectacular piece of engineering itself.

It was basically the entire cargo hold of a C-130, built to be able to rotate and roll 360 degrees continuously.

I think they could do up to nine consecutive revolutions at up to five seconds per revolution and the reason they couldn’t go continuously is that all the cabling to power the lights and everything else inside the set would get wound up."

ERIK NASH

Production & Visual Effects Supervisor on ‘The Mummy’