History of Howdon

In 1974 two engineers, Don Pooley and Howard Miles, formed Howdon Developments, a company engaged in the design and development of mechanical power transmission equipment based in Cwmbran, South Wales, UK. For many years a proliferation of mechanisms and electronic control systems have been offered as an answer to the problem of drive protection. Howdon Developments looked for simpler solutions that would satisfy the requirements of the process industry.

In 1977, Howdon Power Transmission Limited was founded to expand the research and development of products requested by a growing client base. It has always been accepted that a shearpin or ‘mechanical fuse’ is the most effective and reliable long term method of protecting slow/high torque drive systems but because of the problems with fitting and removing round pins, together with the predictability of breaking loads, this method of drive protection had fallen out of favour. Howdon addressed these issues and solved the difficulties with their revolutionary Wedgegard® design, obtaining patents and intellectual property rights.

Howdon at Solids Handling Exhibition, 1984

In 1981, as the business grew, Howdon moved to specially built offices and works in Stroud, Gloucestershire, UK.

Today Howdon has a programme of continual product development and investment working together with customers and suppliers.

We are proud to have enjoyed a long relationship with TWIFLEX, part of the Regal Rexnord Group, as a main Distributor and Stockist for their full range of Industrial Disc Brakes, Couplings and Clutches.

Howdon is involved with the application and supply of mechanical drive systems throughout the world, and is now also working with SVENDBORG BRAKES, BIBBY TURBOFLEX and HUCO ENGINEERING, in addition to TWIFLEX (also all part of Regal Rexnord Group).

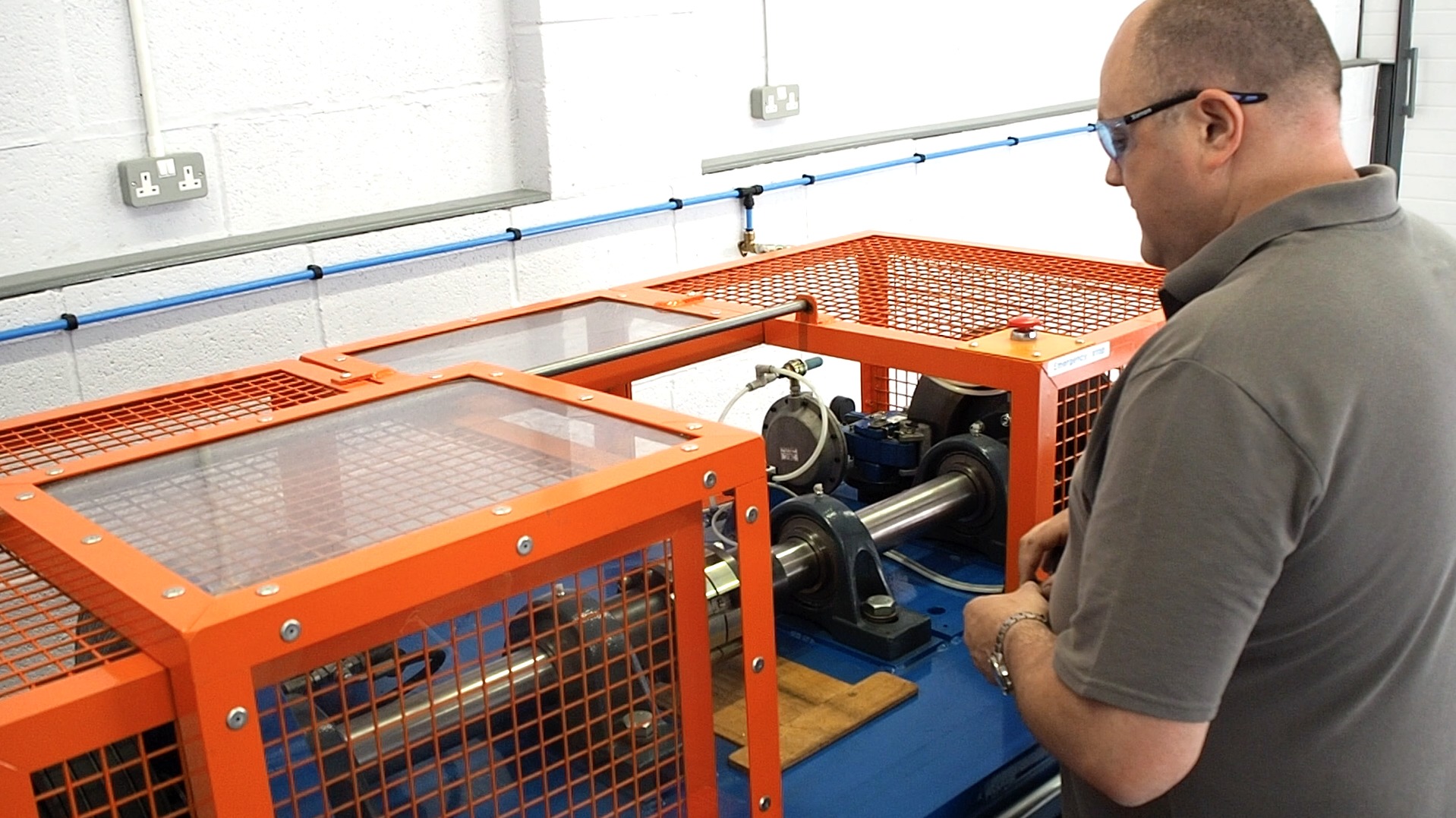

Product Testing

For product testing, Howdon have invested in specially engineered test bed equipment to develop existing products and prove new designs.

Material testing equipment is used during the standard manufacture of steel and brass Wedgepins to ensure accuracy and product reliability.

Pneumatic and hydraulic test beds are employed in the servicing of brake components and the development of brake actuating units.

Research & Development

A continuous programme of product development has always been the policy at HOWDON, meeting new requirements from industry and working together with our partners in mechanical power transmission.

New methods of production have been implemented and test equipment designed to promote the testing of materials supporting new and existing product development.

HOWDON work with customers to solve problems and make bespoke products. This involves design work, prototype manufacture, in-house testing and field trials. Successful projects have been completed with customers worldwide.

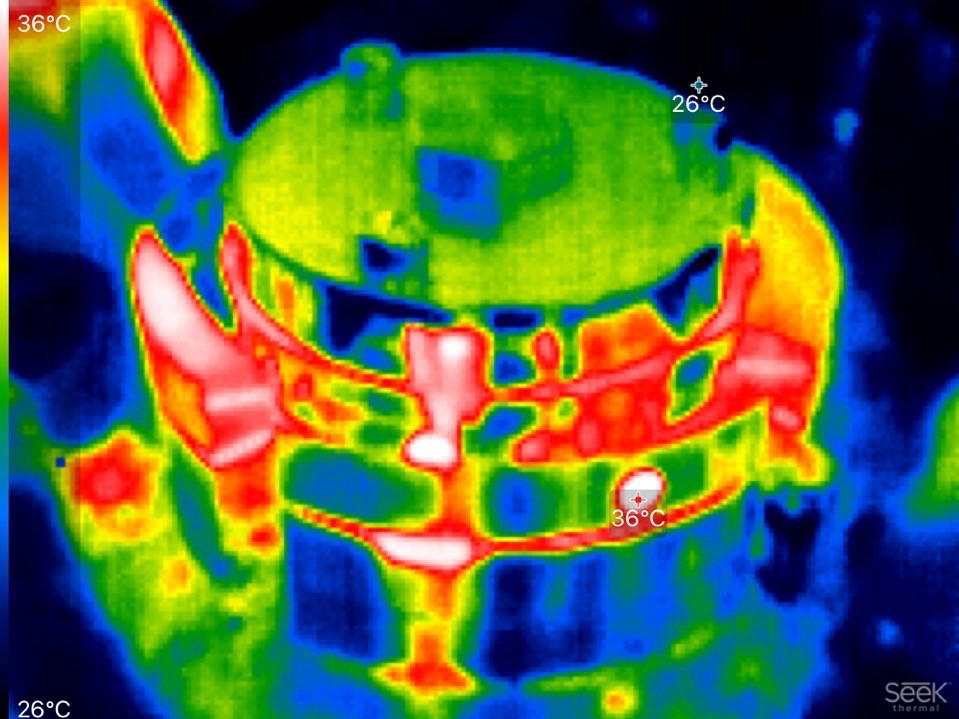

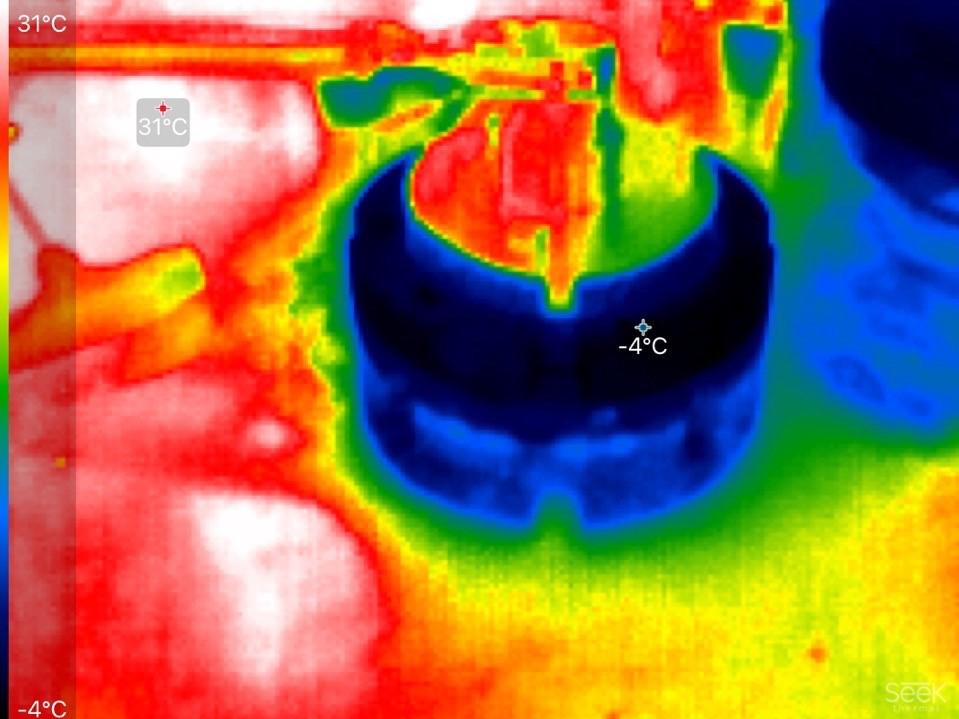

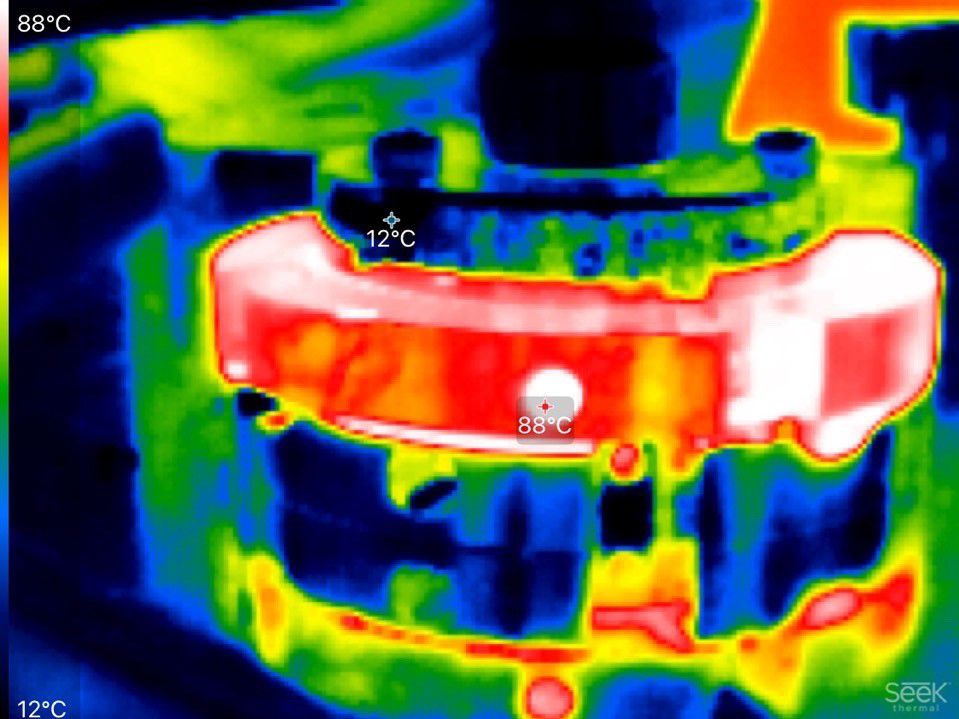

These pictures were taken by a thermal image camera during a bearing temperature test.

Manufacture of Howdon Wedgepins

In order to control the breaking load (release torque) specified for the torque ratings for Brass and Steel Wedgepins™ on Howdon Wedgegard™ products, the following procedure is followed:

Material, Brass or Steel, is supplied with material certification for quality and properties.

Sample Wedgepins™ are manufactured with a range of shear neck diameters. A batch number is allocated to each material.

The sample Wedgepins™ are tested on Linear or Dynamic test beds to confirm the material shear strength. Test figures are then recorded against the batch number.

Shear necks are calculated using the recorded shear strength of each batchof material, to give the torque ratings specified for the size and code of the various Wedgepins™ to be manufactured.

Wedgepins™ are then manufactured to the specified dimensions, and inspected during production.

A random selection of manufactured Wedgepins™ will be tested on Linear or Dynamic test beds as proof samples. These results are recorded against the batch numbers.

All manufactured Wedgepins™ are marked on each end with the size, code and batch number, giving complete traceability.

For Wedgepin™ Torque ratings, please refer to the Torque Sheets for each Wedgegard™ product.

Please note: The release torque provided by an overload protection device can also be subject to the drive speed, together with the rate and frequency of the loads in the drive train. The release figures quoted by Howdon for all Wedgepins™ are calculated using gradually applied loads.